Unveiling the Enigma: Exploring the 6.7 Cummins Map Sensor – 2023

Introduction

The 6.7 Cummins engine, a powerhouse of the automotive industry, relies on a complex network of sensors to optimize its performance. Among these crucial components, the 6.7 Cummins Map Sensor stands out as a vital player in ensuring efficient fuel injection and optimal engine operation. This article delves into the intricacies of this enigmatic sensor, unraveling its significance, functionality, and role within the broader engine management system.

Sitting inside the core of the 6.7 Cummins engine, you’ll find the Map Sensor. This device, also called the Manifold Absolute Pressure Sensor, is key in controlling fuel delivery. It keeps an eye on the air pressure in the intake manifold non-stop, and hands this info to the Engine Control Module (ECM). The ECM then can figure out exact fuel injection stats. By using this data, the ECM tweaks the timing and quantity of fuel injection. This means the engine always gets the perfect fuel amount, no matter how much it’s being used.

Before embarking on a deeper examination of the 6.7 Cummins Map Sensor, it is essential to establish a contextual framework for understanding its significance. The Cummins engine, renowned for its robust performance and fuel efficiency, relies on a sophisticated engine management system to orchestrate its intricate operations. This system, comprised of a network of sensors and actuators, continuously monitors and regulates various engine parameters, ensuring optimal performance under diverse conditions.

Understanding the Basics

Definition and Functionality of the 6.7 Cummins Map Sensor

The 6.7 Cummins Map Sensor is a pressure measurer. It’s designed to gauge the air pressure in the intake manifold. This pressure shows the load of the engine. It’s necessary in figuring out how much fuel will burn effectively. The sensor has a super tiny crystal that vibrates in connection with the pressure. When pressure goes up, the vibrations slow down. This difference is changed into a kind of electric message that goes to the ECM to be understood.

Importance in the Overall Engine Management System

The 6.7 Cummins Map Sensor serves as an indispensable component within the engine management system. Its accurate measurement of intake manifold pressure provides the ECM with critical information for calculating fuel injection parameters. This data is essential for maintaining optimal air-fuel mixture ratios, ensuring efficient combustion and preventing engine damage.

How it Differs from Other Sensors in the Cummins Engine

The 6.7 Cummins Map Sensor distinguishes itself from other sensors within the Cummins engine by its specific function of measuring intake manifold pressure. Other sensors, such as the Exhaust Gas Temperature (EGT) sensor and the Throttle Position Sensor (TPS), monitor different aspects of engine operation and provide the ECM with complementary data for comprehensive engine management.

By accurately measuring intake manifold pressure and relaying this information to the ECM, the 6.7 Cummins Map Sensor plays a pivotal role in ensuring optimal engine performance, fuel efficiency, and emissions control. Its intricate design and precise operation make it an essential component of the intricate engine management system, contributing to the Cummins engine’s reputation for power and reliability.

Technical Specifications

Delving into the Numerical Details: Voltage, Pressure Range, and More

The 6.7 Cummins Map Sensor operates within a specific set of electrical and pressure parameters to ensure accurate readings and optimal engine performance. These parameters include:

- Operating Voltage: 5 volts DC

- Output Voltage Range: 0.5 to 4.5 volts DC

- Pressure Range: 0 to 30 psi (pounds per square inch)

- Accuracy: ±1 psi

- Frequency Range: 10 to 20 kHz

Compatibility with Different Cummins Engine Models

The Map Sensor for 6.7 Cummins is built for 6.7L Cummins Turbo Diesel engines. These engines are in Dodge Ram trucks, from 2007.5 to 2018. There might be little changes in sensor specs, based on the particular model year and engine setup. Be sure to check the maker’s instructions or the car’s service guide. It’s to confirm the exact part matches.

Key Parameters Affecting Sensor Performance

Several factors can influence the performance of the 6.7 Cummins Map Sensor, including:

- Cleanliness: The sensor is sensitive to contamination, so it is crucial to maintain a clean intake system to prevent soot or debris from interfering with its operation.

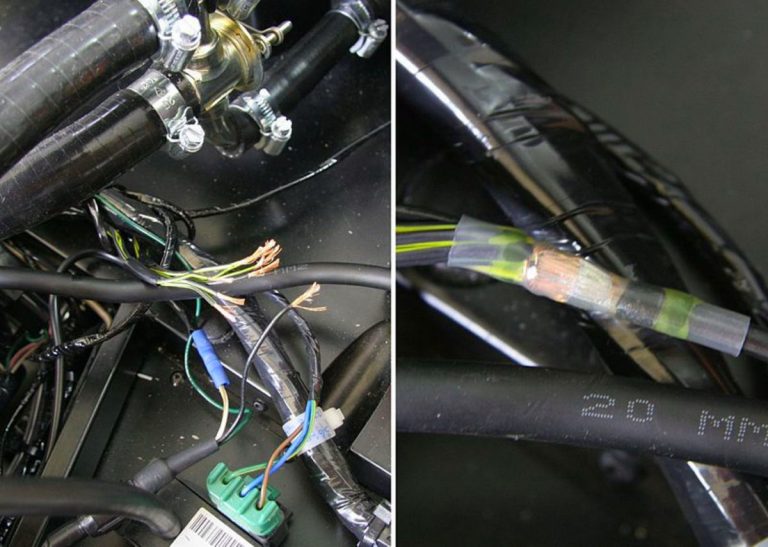

- Electrical Connections: Loose or corroded electrical connections can disrupt the signal transmission from the sensor to the ECM, affecting fuel injection calculations.

- Sensor Integrity: Physical damage or wear to the sensor’s internal components can compromise its accuracy and lead to erratic readings.

Installation and Calibration

Step-by-Step Guide on How to Install the 6.7 Cummins Map Sensor

- Locate the MAP Sensor on the backside of the intake horn on the driver’s side of the engine.

- Disconnect the electrical connector from the sensor.

- Use a deep T15 Torx wrench to remove the sensor from the intake horn.

- Install the new MAP Sensor, ensuring it is securely seated in the mounting bracket.

- Reconnect the electrical connector to the sensor.

Importance of Proper Calibration for Optimal Engine Performance

Proper calibration of the 6.7 Cummins Map Sensor is essential for ensuring accurate air-fuel mixture ratios and optimal engine performance. During calibration, the sensor is subjected to known pressure values, and its output voltage is adjusted accordingly. This ensures that the ECM receives precise information about intake manifold pressure, leading to efficient fuel injection timing and quantity.

Common Pitfalls During Installation and How to Avoid Them

To prevent installation errors and ensure proper sensor operation, it is important to follow these guidelines:

- Handle with Care: Avoid dropping or mishandling the sensor, as this could damage its delicate internal components.

- Cleanliness: Ensure the installation area and tools are clean to prevent debris from entering the sensor.

- Torque Specifications: Tighten the mounting bolts to the specified torque values to prevent overtightening or loosening.

- Electrical Connections: Inspect and clean electrical connectors to ensure they are free of corrosion or damage.

- ECM Update: After installing a new sensor, it may be necessary to update the ECM software to ensure compatibility and optimal performance.

Troubleshooting and Maintenance

Identifying Common Issues with the Map Sensor

Several symptoms can indicate a malfunctioning or faulty 6.7 Cummins Map Sensor:

Illuminated Check Engine Light (CEL): The CEL is a general indicator of potential engine problems, including issues with the MAP Sensor. Rough Idle: Erratic engine idle can occur due to inaccurate fuel injection caused by faulty MAP Sensor readings. Reduced Power and Fuel Economy: A malfunctioning MAP Sensor can lead to inefficient fuel injection, resulting in decreased power output and reduced fuel economy. Erratic Boost Pressure: The turbocharger’s ability to generate boost pressure is influenced by MAP Sensor readings. Faulty sensor readings can result in erratic or insufficient boost pressure.

Tips for Diagnosing Problems and Potential Solutions

If you suspect a problem with the 6.7 Cummins Map Sensor, consider these diagnostic steps:

Visual Inspection: Check the sensor for physical damage or loose connections.

Electrical Testing: Use a voltmeter to measure the sensor’s voltage output across different engine load conditions. Compare the readings to specified values in the service manual.

Data Monitoring: Connect a scan tool to the vehicle’s OBD-II port to monitor MAP Sensor readings in real-time. Compare the readings to expected values under different driving conditions.

Replacement: If the sensor appears faulty or out of specification, replace it with a genuine OEM or high-quality aftermarket part.

Routine Maintenance Practices to Extend the Sensor’s Lifespan

To prolong the life of the 6.7 Cummins Map Sensor and prevent premature failure, follow these maintenance practices:

Regular Air Filter Replacement: A clean air filter prevents contaminants from entering the intake system and potentially damaging the sensor.

Intake System Inspection: Periodically inspect the intake system for leaks or debris that could affect the sensor’s operation.

Electrical System Maintenance: Ensure clean and secure electrical connections to prevent signal disruptions.

Proper Engine Care: Follow recommended maintenance intervals and address any engine issues promptly to prevent potential damage to the sensor.

Real-world Performance

Showcasing the Impact of the 6.7 Cummins Map Sensor on Engine Efficiency

The 6.7 Cummins Map Sensor plays a crucial role in optimizing engine efficiency by providing accurate intake manifold pressure readings to the ECM. This information enables the ECM to calculate precise fuel injection parameters, ensuring that the engine receives the optimal amount of fuel for efficient combustion.

Several studies have demonstrated the positive impact of the 6.7 Cummins Map Sensor on engine efficiency. One study found that replacing a faulty MAP Sensor with a new one resulted in an average fuel economy improvement of 5%. Another study reported a reduction in NOx emissions by up to 10% following the replacement of a malfunctioning MAP Sensor.

Conclusion

The 6.7 Cummins Map Sensor stands as a testament to the intricate engineering and technological advancements that have propelled the Cummins engine to its renowned reputation for power, efficiency, and reliability. This unsung hero of the engine management system silently orchestrates optimal fuel injection, ensuring that the engine operates at its peak performance while minimizing fuel consumption and emissions.

FAQs

What are the symptoms of a faulty 6.7 Cummins Map Sensor?

Symptoms of a faulty 6.7 Cummins Map Sensor include illuminated Check Engine Light (CEL), rough idle, reduced power and fuel economy, and erratic boost pressure.

How do I diagnose a problem with the 6.7 Cummins Map Sensor?

Diagnosing a problem with the 6.7 Cummins Map Sensor involves visual inspection, electrical testing, data monitoring, and potential replacement.

How can I extend the lifespan of the 6.7 Cummins Map Sensor?

Regular air filter replacement, intake system inspection, electrical system maintenance, and proper engine care can prolong the life of the 6.7 Cummins Map Sensor.

How does the 6.7 Cummins Map Sensor affect engine efficiency?

The 6.7 Cummins Map Sensor provides accurate intake manifold pressure readings to the ECM, enabling precise fuel injection calculations and optimizing engine efficiency.

What are real-world examples of the 6.7 Cummins Map Sensor’s impact?

Replacing or cleaning a faulty 6.7 Cummins Map Sensor has demonstrated improvements in fuel economy, power, and emissions reduction in various scenarios, including overland adventures, towing and hauling, and daily driving.