Multi-Axis Acceleration Sensor Missing Calibration; What To Do?

A multi-axis acceleration sensor is a device that is used to measure acceleration in multiple directions. It is typically used to measure the acceleration of an object in three dimensions: up/down, left/right, and front/back. It can also measure angular acceleration. These sensors are used in many applications, such as robotics, navigation, gaming, and automotive control systems. They are used to detect motion, position, and orientation.

In this article, you will find what to do when the multi-axis acceleration sensor missing calibration. So stick around until the end to find out what you’ve been looking for.

Table of Contents

What is multi-axis acceleration sensor module?

A multi-axis acceleration sensor module is an electronic device used to measure acceleration in multiple directions.

It is typically composed of a microelectromechanical system (MEMS) accelerometer, which is a type of integrated circuit (IC) that contains a number of small mechanical elements, such as springs and masses, to measure acceleration along the three axes of motion (X, Y, and Z).

The MEMS accelerometer is capable of measuring acceleration in all three directions, and can also be used to detect and measure shock, tilt, vibration, and rotation. The data from the module can be used for a variety of applications, such as navigation and motion control, robotics, aircraft and automotive design, and in medical and industrial applications.

It can also be used to detect and measure changes in velocity and to sense changes in the environment (such as changes in temperature, pressure, light, and sound). The output from the module is often processed to determine the magnitude, frequency, and direction of the acceleration.

Multi-axis acceleration sensor symptoms.

When a multi-axis acceleration sensor fails, it will cause the system to become unstable and inaccurate. This can lead to problems such as inaccurate readings, inaccurate calculations, and faulty control signals. In some cases, the system may even shut down completely.

1. Low sensitivity: The output of the sensor may be too low for the application.

2. Unstable readings: The output of the sensor may be erratic and not consistent over time.

3. Drift: The output of the sensor may drift over time, meaning its output is changing without any input.

4. Poor resolution: The output of the sensor may not be accurate enough for the application.

5. Hysteresis: The output of the sensor may be affected by the previous measurement, meaning its output is not linear.

6. Nonlinearity: The output of the sensor may not be linear, meaning the output is not proportional to the input.

“Multi-Axis Acceleration Sensor Missing Calibration”; What To Do?

When a multi-axis acceleration sensor is missing calibration, the first step is to identify the type of sensor used and the manufacturer.

Once the manufacturer is identified, contact the manufacturer to obtain the calibration procedure or instructions. If instructions are not available, then the sensor will need to be calibrated using a specialized tool such as a dynamometer.

This tool can measure the sensor’s response to various levels of input, allowing for the calibration to be performed. Once the calibration is complete, the sensor should be tested to ensure that it is properly calibrated and functioning correctly.

“Lost communication with multi-axis acceleration sensor module”; What to do?

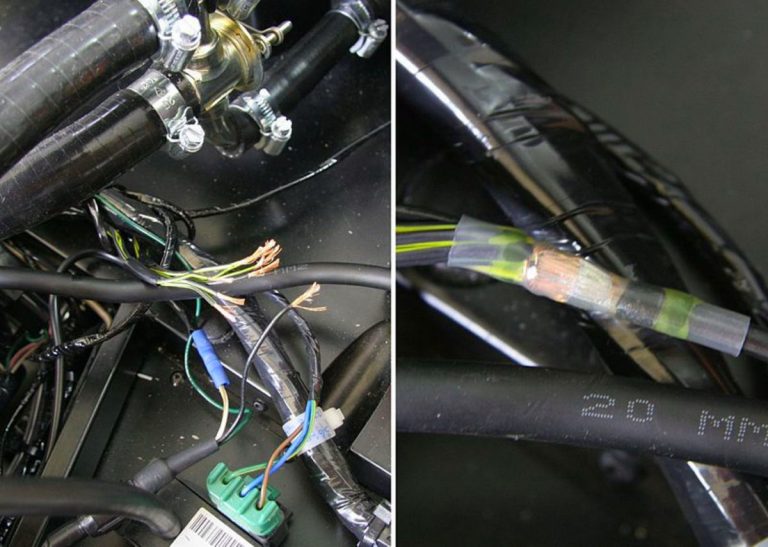

If communication with a multi-axis acceleration sensor module is lost, the first step is to check the power supply. Make sure the power supply is providing the correct voltage and amperage.

If the power supply is okay, check the connections between the module and the rest of the system to ensure that all wires are correctly connected and that no wires have become disconnected.

If the connections are okay, check the settings on the module to make sure they are correct and that any necessary configuration changes have been made. If all of these steps have been completed and communication is still not established, it may be necessary to replace the module.

What is code U0125?

Code U0125 is a diagnostic trouble code which indicates a malfunction in the vehicle’s power steering system. It is often caused by a failure in the steering motor or the steering control module. Symptoms of this code can include difficulty steering, a decrease in power steering assist, or an illuminated check engine light.

How to troubleshoot the Multi axis acceleration sensor?

1. Check the connections: Check all the connections to the sensor and ensure they are secure and properly connected.

2. Check the power supply: Ensure that the power supply to the sensor is within the required specifications and that the voltage is steady.

3. Check the environment: Ensure that the environment where the sensor is installed is free of any vibration, dust, and other particles that could affect the operation of the sensor.

4. Check the output: Ensure that the output of the sensor is within the expected range.

5. Check for mechanical damage: Inspect the sensor for any mechanical damage that may be affecting its operation.

6. Software updates: Ensure that the software used to control the sensor is up to date.

7. Calibrate the sensor: If the output of the sensor is not within the expected range, then it may need to be recalibrated.