Exploring the Kaleidoscope of various industries: An In-Depth Analysis – 2023

Why are Map Sensors important in various industries?

In this newsletter, we are able to discover the unique programs of map sensors in diverse industries and communicate their significance in optimizing performance. Map sensors are an important detail of any navigation device. They help to calculate the precise position of a car on a map and provide real-time records approximately the encircling place. This records is used to generate the usage of directions and provide updates on traffic situations. In addition to navigation, map sensors have some of exclusive programs in various industries. Let’s take a more in-depth look at some of those programs.

Introduction – various industries

Map sensors, also called manifold absolute pressure sensors, play a important position in various industries. From car to aerospace, those sensors have become an vital problem for optimizing performance and performance. In this segment, we can delve into the importance of map sensors in awesome fields and discover how they contribute to the overall functioning of complicated structures.

- Automotive Industry: A. Engine Efficiency: Map sensors provide correct measurements of the stress in the intake manifold, permitting the engine control unit (ECU) to calculate the most reliable air-gasoline ratio. This ensures efficient combustion, leading to better gas economy and reduced emissions. B. Turbocharger Control: Map sensors help in regulating the increase strain generated by means of turbochargers, ensuring most efficient engine performance.

- Aerospace Industry: A. Altitude Detection: Map sensors are important for altitude detection in aircraft. By measuring the pressure in the atmosphere, those sensors assist in as it should be figuring out the aircraft’s top above sea level. B. Engine Monitoring: In aircraft engines, map sensors provide vital facts about the consumption manifold stress, allowing precise modifications for most advantageous gas-air combination at various altitudes.

- Industrial Automation: A. Combustion Control: Map sensors enable precise monitoring and control of combustion techniques in business gadget consisting of boilers and furnaces. Accurate stress readings assist optimize gas consumption and maintain solid combustion. B. Energy Efficiency: By tracking stress changes in industrial structures, map sensors make a contribution to optimizing power utilization and lowering waste.

What is the Role of a Map Sensor?

Map sensors play a essential position in various industries through imparting crucial facts to optimize overall performance. Understanding their significance is fundamental to improving efficiency and attaining better consequences.

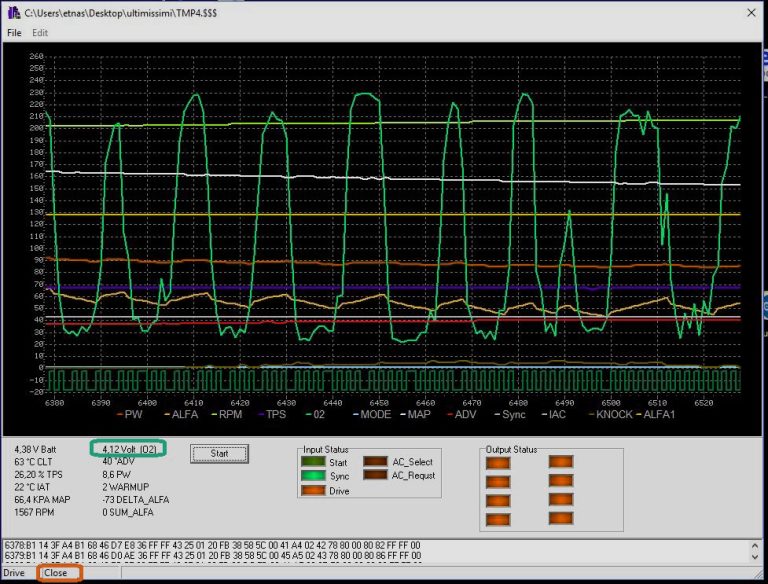

- The Function of a Map Sensor: Map sensors, brief for Manifold Absolute Pressure sensors, degree the atmospheric strain inside the consumption manifold of an engine. By monitoring the pressure modifications, map sensors help in regulating gas transport and ignition timing. This records permits the engine manipulate unit (ECU) to make essential modifications for ideal performance.

- Automotive Industry: In the car subject, map sensors are essential for preserving engine performance, emissions control, and fuel economy. By accurately measuring manifold stress, map sensors useful resource in controlling air-to-gas ratios and turbocharger boost ranges. This ensures smooth engine operation and allows meet emission requirements.

- Aviation Industry: Map sensors additionally play a critical role inside the aviation zone. They are utilized in aircraft engines to display and adjust fuel-air combinations at distinctive altitudes. The information gathered through map sensors allows for most appropriate combustion performance, ensuring smooth engine overall performance and reducing the chance of engine damage.

- Industrial Applications: Map sensors are hired in numerous commercial packages in which unique stress measurements are necessary. They are used in structures inclusive of HVAC (Heating, Ventilation, and Air Conditioning) gadget, pneumatic controls, and hydraulic machinery. By appropriately detecting pressure modifications, map sensors facilitate particular manipulate and make sure efficient operation.

Automotive Applications – various industries

Map sensors play a critical function in diverse industries, specifically in car programs. These sensors are employed in automobiles to screen and measure the manifold absolute strain (MAP) within the consumption manifold. By appropriately determining the stress, map sensors assist optimize engine overall performance and ensure green gasoline combustion.

- Engine Control: Map sensors are an necessary a part of the engine control gadget in contemporary cars. They provide real-time records to the engine manipulate unit (ECU) approximately the air strain in the manifold. This records assists the ECU in making essential changes to optimize airflow, gasoline injection, and ignition timing. As a end result, the engine can perform at height performance and supply premiere strength.

- Fuel Efficiency: Proper fuel-air aggregate is crucial for fuel efficiency. Map sensors check the intake manifold pressure, permitting the ECU to correctly calculate the appropriate amount of gasoline wished for combustion. This unique measurement permits efficient fuel usage, minimizing wastage and enhancing basic fuel economy.

- Emission Control: Map sensors additionally resource in emission control. By monitoring manifold pressure, these sensors assist the ECU in making sure the proper air-gasoline ratio for combustion. Maintaining the finest aggregate helps lessen harmful emissions, ensuring compliance with emission policies and minimizing the environmental impact of automobiles.

- Turbocharged Engines: In turbocharged engines, map sensors are specially essential. These sensors reveal the stress on the turbocharger outlet, presenting vital records to the ECU. The ECU then adjusts the improve pressure and gasoline transport thus, optimizing the overall performance of turbocharged engines.

Various industries Applications

Map sensors play a critical function in numerous industries, contributing to the optimization of overall performance and performance in one of a kind programs. Let’s explore how map sensors are utilized in a few key commercial sectors:

The Role in Automotive Industry:

In the automotive sector, map sensors are integral additives of engine management structures. They measure manifold absolute pressure, presenting actual-time information to the engine manipulate unit (ECU). This information enables the ECU decide the engine’s load and optimize the air-fuel combination for progressed combustion efficiency. As a end result, map sensors play a crucial role in improving fuel financial system, emissions control, and overall engine performance.

The Role in HVAC Systems:

Heating, ventilation, and aircon (HVAC) systems depend on map sensors to regulate airflow and make sure an excellent indoor climate. By detecting adjustments in pressure in the system, map sensors enable first-rate-tuning of temperature and humidity manage. This ensures maximum comfort for occupants at the same time as retaining energy efficiency in industrial, residential, and industrial homes.

- Map sensors permit HVAC systems to adapt to varying environmental situations, making sure most effective overall performance and power savings.

- High-nice map sensors are vital for accurate and reliable temperature and pressure measurements in HVAC packages.

The Role in Aerospace Industry:

In the aerospace zone, map sensors are crucial for aerospace engine overall performance. They assist in measuring atmospheric strain and altitude, offering vital statistics for the control device. This statistics enables pilots and engineers optimize aircraft engine performance, making sure clean operation at numerous altitudes and climates.

The Role in Various Industries Automation

Map sensors discover extensive usage in business automation programs. They allow precise tracking and manage of strain inside pneumatic systems, ensuring accurate operation of machinery and equipment. Map sensors make contributions to the protection, efficiency, and reliability of methods in production, packaging, and material handling industries.

The Role in Marine Industry:

Map sensors also are enormous within the marine enterprise, mainly in marine engines. By providing accurate facts on intake manifold strain, map sensors help optimize gas injection and ensure efficient combustion. This ends in stepped forward vessel overall performance, fuel financial system, and reduced emissions in marine transportation and offshore operations.

Benefits of Map Sensors

Map sensors, additionally called Manifold Absolute Pressure sensors, play a essential function in numerous industries. Let’s explore some of the important thing blessings they provide:

- Improved Engine Performance: Map sensors provide vital data approximately the air strain entering the engine. This information facilitates the engine manage unit (ECU) optimize gas injection, air-to-gas ratio, and ignition timing for green combustion. With correct measurements from map sensors, engines can supply premiere performance, improved strength output, and decreased emissions.

- Enhanced Fuel Efficiency: Map sensors contribute to better gasoline financial system by using ensuring the engine receives the proper amount of gasoline based totally on the air stress. By appropriately measuring the stress, map sensors assist obtain the appropriate air-to-fuel ratio, stopping fuel wastage and maximizing gas performance. This is mainly crucial in industries reliant on heavy machinery and vehicles, in which gasoline fees can extensively impact operational costs.

- Precise Altitude Compensation: In packages regarding altitude versions including aviation or mountainous areas, map sensors play a important position in adjusting engine overall performance. They offer the vital records to hold the specified air-gas combination even at unique altitudes, ensuring regular overall performance irrespective of the region.

- Optimal Turbocharger Control: Turbocharged engines rely on map sensors to display the stress ranges pre- and put up-faster. This statistics facilitates in optimizing the turbocharger’s performance and preventing troubles like over-boosting, that may result in engine harm. By regulating the turbocharger correctly, map sensors contribute to extended engine life and improved common efficiency.

- Effective Diagnostics: Map sensors help in diagnosing capacity engine problems via tracking the consumption manifold pressure. Any anomalies detected by the map sensors can imply troubles such as clogged air filters, leaks in the intake device, or even engine misfires. This allows mechanics or technicians to discover and address problems promptly, minimizing downtime and steeply-priced upkeep.

Drawbacks of Map Sensors

While map sensors are important in various industries, they are now not with out their barriers. Understanding those drawbacks is important for optimizing the performance of those sensors.

• Temperature Sensitivity: Map sensors can be sensitive to temperature adjustments. Extreme warm or bloodless conditions can also have an effect on their accuracy, leading to capability issues in readings. It’s vital to bear in mind temperature fluctuations whilst counting on map sensor records.

• Airflow Restrictions: Map sensors depend on the consumption manifold’s airflow to measure pressure. Any regulations or obstructions in the consumption system can impact the sensor’s accuracy. It’s important to often investigate and maintain the consumption gadget to make certain proper functioning of the map sensor.

• Resolution and Response Time: The resolution and reaction time of map sensors can range depending on their first-class and design. Lower-first-class sensors may also exhibit slower response instances, leading to delays in detecting adjustments in strain. Investing in top notch map sensors can mitigate this difficulty.

• Limited Altitude Compensation: Map sensors calculate air stress based totally on altitude, and at the same time as they can make amends for moderate changes, they’ll not be appropriate for excessive altitudes. In excessive-altitude environments, specialized sensors with more suitable altitude repayment may be required. To conquer those boundaries, it’s far vital to bear in mind the specific necessities of your industry and select map sensors that are appropriate on your software. Regular upkeep, calibration, and investing in wonderful sensors can assist optimize their overall performance and reliability.

Conclusion – various industries

In conclusion, map sensors play a crucial position in optimizing overall performance across various industries. From automotive to aerospace, these sensors are key components in making sure green functioning of engines and structures. By appropriately measuring manifold stress and temperature, map sensors allow cars, plane, or even industrial machinery to make real-time modifications and supply pinnacle-nice overall performance. These sensors are relied upon through mechanics, engineers, and specialists in wonderful fields to display screen and manage the air-gasoline ratio, enhance strain, and common engine average overall performance. With their capability to provide accurate and dependable facts, map sensors make contributions to extra superb fuel economic system, decreased emissions, and progressed safety. It is apparent that the significance of map sensors cannot be overstated inside the international of present day generation and enterprise.